Industrial Automation and Robotic Assembly Lines

In the realm of manufacturing, the symphony of robotics unfolds with industrial automation and robotic assembly lines. This movement explores how robotics harmoniously choreograph manufacturing processes, orchestrating intricate dances of efficiency and precision. Robotic arms and machines work in harmonious unison, assembling products with flawless accuracy and tireless repetition. The symphony resonates as factories embrace robotic assembly lines, composing a melodious cadence of increased production rates, reduced errors, and streamlined operations. As the harmonies of automation deepen, manufacturing landscapes evolve into symphonic orchestrations of robotic efficiency.

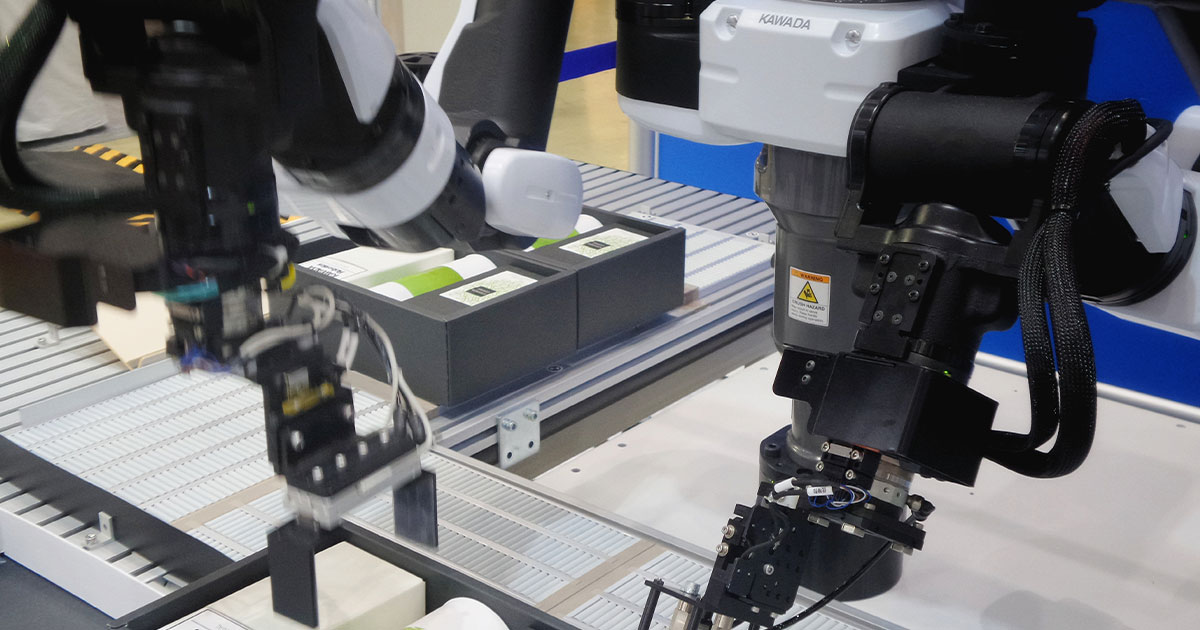

Collaborative Robots (Cobots) and Human-Machine Harmony

The symphony of robotics extends its reach with collaborative robots, affectionately known as cobots. This movement delves into how cobots harmoniously collaborate with human workers, creating a symphonic partnership that enhances productivity and safety. Cobots join the manufacturing ensemble, working side by side with humans, sharing tasks, and leveraging their harmonious synergy to create a melodious blend of human expertise and robotic precision. The symphony resonates as cobots orchestrate a harmonious dance of collaboration, revolutionizing manufacturing processes and cultivating an environment where human-machine harmony sings the cadence of enhanced production and job satisfaction.

Quality Control and Robotic Inspection

The symphony of robotics resonates through the domain of quality control and robotic inspection in manufacturing. This movement unveils how robotic systems harmoniously scrutinize products, materials, and components to ensure flawless quality. Robotic sensors and cameras orchestrate a harmonious symphony of precision measurements, detecting imperfections and deviations with meticulous accuracy. The symphony resonates as robotic inspection processes create a melodic cadence of consistent quality assurance, ensuring that each manufactured piece sings in harmonious alignment with stringent standards. As the symphony deepens, manufacturing landscapes resonate with the harmonious notes of flawless quality control.

Material Handling and Logistics Symphony

The harmonious fusion of robotics extends to material handling and logistics, composing a transformative symphony in manufacturing. This movement delves into how robotic systems orchestrate the efficient movement and transportation of raw materials and finished products. Robotic arms, autonomous vehicles, and drones collaborate in harmonious choreography, transporting materials with precision and expediting logistics processes. The symphony resonates as robotic logistics orchestrate a melodic dance of streamlined supply chains, reduced lead times, and harmonious inventory management. As the harmonies evolve, manufacturing landscapes are reshaped into symphonic arenas of agile material handling and seamless logistics operations.

Customization and Flexible Manufacturing Ensemble

In the grand finale, the symphony of robotics reaches its zenith with customization and flexible manufacturing ensembles. This movement explores how robotics harmoniously empower the creation of customized products and flexible production processes. Robotic systems, guided by sophisticated algorithms, harmonize to dynamically adapt and configure manufacturing setups, creating a melodious cadence of on-demand customization. The symphony resonates as robotic ensembles craft a harmonious orchestra of personalized products, redefining manufacturing paradigms and heralding a future where flexibility and customization resonate in harmonious unison.

The symphony of robotics in manufacturing reaches its culmination, with each subheading contributing a unique melody to the composition. From industrial automation’s efficient ballet to cobots’ human-machine harmonies, each movement showcases the transformative potential of robotics. As the symphony continues, it beckons manufacturers and industries to embrace the ensemble, crafting a harmonious future where technology and human ingenuity create a symphonic resonance of efficiency, precision, and innovation.

Repetitive and Dangerous Task Orchestration

The symphony of robotics further extends to the orchestration of repetitive and dangerous tasks in manufacturing. This movement delves into how robotics harmoniously alleviate human workers from mundane and hazardous duties. Robotic arms, exoskeletons, and automated machinery compose a harmonious ensemble, executing tasks that demand precision and endure risk. The symphony resonates as robotics symphonize with labor-intensive processes, cultivating a safer and more harmonious work environment. As the harmonies deepen, manufacturing landscapes resonate with the melodious cadence of improved worker safety and optimized task execution.

3D Printing and Robotic Additive Manufacturing

The symphony of robotics evolves into the realm of 3D printing and robotic additive manufacturing. This movement unveils how robotic systems harmoniously collaborate with 3D printing technologies, orchestrating the layer-by-layer creation of intricate designs. Robotic arms, guided by design algorithms, create a harmonious dance of additive manufacturing, crafting complex structures with precision and versatility. The symphony resonates as 3D printing and robotics create a melodic cadence of rapid prototyping, reduced material waste, and limitless design possibilities. As the harmonies deepen, manufacturing landscapes transform into symphonic stages of innovative production and agile design.

Maintenance and Robotic Servicing Ensemble

The harmonious fusion of robotics extends to maintenance and robotic servicing ensembles in manufacturing. This movement delves into how robotics harmoniously conduct maintenance tasks, inspecting, repairing, and servicing machinery and equipment. Robotic systems navigate harmoniously through intricate machinery, performing tasks that ensure operational longevity and reduce downtime. The symphony resonates as robotic servicing ensembles create a melodic cadence of predictive maintenance, optimizing equipment performance and harmonizing with efficient operations. As the harmonies evolve, manufacturing landscapes resonate with the harmonious notes of prolonged equipment life and reduced maintenance costs.

Data-Driven Optimization and Analytics Symphony

The symphony of robotics resonates through data-driven optimization and analytics in manufacturing. This movement unveils how robotic systems harmoniously gather and analyze vast amounts of manufacturing data to inform process improvements and operational efficiencies. Robotic sensors and AI-powered algorithms orchestrate a harmonious symphony of real-time data insights, guiding manufacturing decisions with precision and insight. The symphony resonates as data-driven optimization ensembles create a melodic cadence of continuous improvement, transforming manufacturing landscapes into symphonic arenas of agility and data-driven excellence. As the harmonies deepen, industries compose a future where data and robotics harmonize to elevate manufacturing performance to new heights.

Ethical Considerations and Workforce Harmony

In the final crescendo, the symphony of robotics in manufacturing echoes with ethical considerations and workforce harmony. This movement explores how harmonious deployment of robotics respects ethical guidelines, ensures human well-being, and fosters workforce harmony. The symphony resonates through the orchestration of balanced human-robot collaboration, acknowledging the importance of human creativity, decision-making, and empathy in the manufacturing ensemble. As the symphony reaches its zenith, it invites industries to embrace the harmonious blend of technology and humanity, crafting a future where robotics and workforce harmonize to create a symphony of innovative, ethical, and inclusive manufacturing.

The symphony of robotics in manufacturing concludes its opus, each subheading contributing a unique resonance to the composition. From 3D printing’s additive harmonies to data-driven analytics’ symphonic insights, each movement showcases the transformative role of robotics. As the symphony resounds, it beckons manufacturers and industries to join the symphonic ensemble, crafting a harmonious future where technology and human ingenuity compose a resonant melody of efficiency, innovation, and ethical harmony.

Energy Efficiency and Sustainable Manufacturing

The symphony of robotics continues to resonate with energy efficiency and sustainable manufacturing. This movement delves into how robotics harmoniously contribute to reducing energy consumption and promoting eco-friendly practices in manufacturing. Robotic systems orchestrate precise and optimized operations, minimizing wastage and energy expenditure. The symphony resonates as robotics and sustainable practices create a melodic cadence of reduced carbon footprint and resource conservation. As the harmonies deepen, manufacturing landscapes transform into symphonic stages of environmental responsibility and sustainable production.

Robotic Training and Skill Development

The harmonious fusion of robotics extends to robotic training and skill development in manufacturing. This movement unveils how robotics harmoniously empower workers with new skill sets to operate and interact with advanced robotic systems. Robotic training programs, guided by instructional algorithms, create a harmonious dance of upskilling, fostering a workforce capable of seamlessly collaborating with robotic ensembles. The symphony resonates as robotic training initiatives craft a melodic cadence of enhanced workforce adaptability, ensuring a harmonious integration of human expertise and robotic precision.

Human-Centric Design and Ergonomics

The symphony of robotics resonates through human-centric design and ergonomics in manufacturing. This movement explores how robotics harmoniously contribute to designing ergonomic workspaces and processes that prioritize worker well-being. Robotic systems collaborate in harmonious orchestration, enhancing ergonomics by automating physically demanding tasks and optimizing workstations for human comfort. The symphony resonates as human-centric design and robotics create a melodic cadence of improved worker health, reduced strain, and harmonious collaboration. As the harmonies evolve, manufacturing environments transform into symphonic spaces that prioritize both productivity and worker welfare.

Ethical Robotics and Inclusive Automation

The symphony of robotics reaches a poignant note with ethical robotics and inclusive automation. This movement delves into how harmonious deployment of robotics ensures inclusive access and respects ethical considerations. Robotic systems are orchestrated to empower diverse individuals, fostering a harmonious symphony of inclusivity and equal opportunity. The symphony resonates as ethical robotics create a melodic cadence of diverse workforce engagement and social responsibility. As the harmonies deepen, industries compose a future where robotics and ethics harmonize to create a symphony of technology that resonates with societal values and inclusion.

Industry Collaboration and Technological Harmony

In the grand finale, the symphony of robotics in manufacturing crescendos with industry collaboration and technological harmony. This movement explores how harmonious collaboration between industries, researchers, and technology developers shapes a future where robotics orchestrate transformative advancements. Robotic systems are united in a symphony of innovation, interweaving technology and expertise to harmoniously solve complex manufacturing challenges. The symphony resonates as collaborative efforts create a melodic cadence of collective progress and harmonious technological evolution. As the harmonies reach their zenith, it invites industries to join hands in crafting a future where robotics and human ingenuity create a symphony of shared innovation, prosperity, and harmonious technological evolution.

The symphony of robotics in manufacturing reaches its grand conclusion, each subheading contributing a unique resonance to the composition. From sustainable manufacturing’s eco-friendly harmonies to ethical robotics’ inclusive cadence, each movement showcases the transformative potential of robotics. As the symphony echoes, it beckons manufacturers, workers, and industries to join the harmonious ensemble, crafting a future where technology and human collaboration compose a resonant melody of efficiency, sustainability, and ethical harmony.